SVG (Static Var Generator) is engineered for precision power factor correction and harmonic filtering. Our Static Var Generator (SVG) employs top-tier IGBT and DSP components to deliver sub-5ms response times, ensuring dynamic reactive power compensation. The modular design enhances thermal efficiency, while advanced protection circuits halt PWM output within 2 microseconds to safeguard critical components. Cloud-connected capabilities enable remote SVG monitoring, optimizing grid stability and improving power quality. Ideal for industrial applications requiring rapid power factor correction and harmonic mitigation, our SVG technology combines speed, reliability, and smart grid integration.

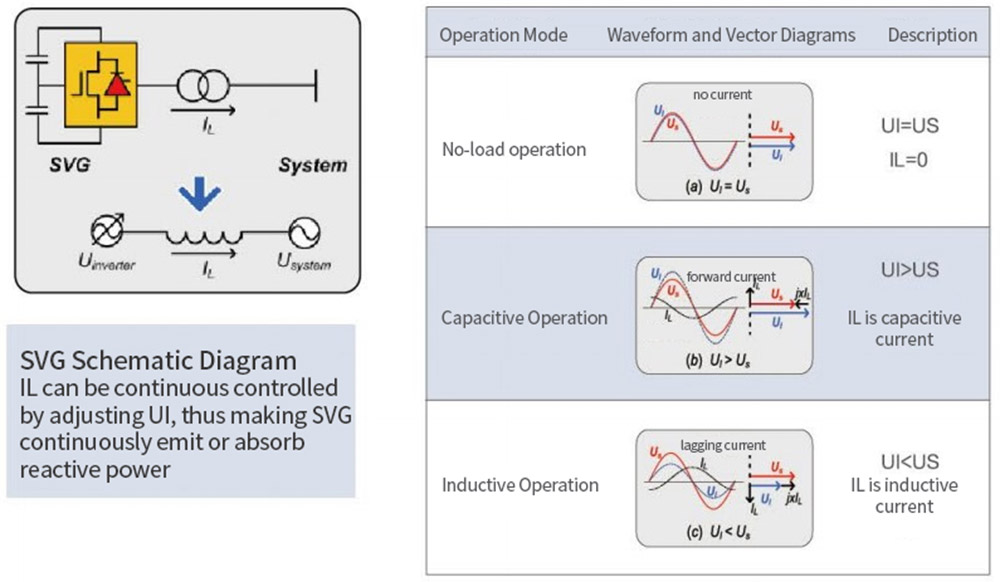

Based on the high power converter, the core is the voltage-type inverter, and the DC side uses DC capacitance as energy storage elements to provide voltage support. In operation, it is equivalent to a three-phase AC power supply with adjustable voltage, phase and amplitude.

The normal operation of the inverter depends on the voltage support of the DC side. When the inverter is connected into the AC power supply, each IGBT reverse freewheeling diode forms a rectifier to charge the DC capacitor. After normal operation, the energy storage of the DC capacitor will be used to satisfy the internal loss of the inverter, and the capacitor voltage will drop, the capacitor must be continuously charged to keep the voltage within the working range. Through changing the amplitude of the inverter output voltage to achieve the purpose of emitting or absorbing reactive power.

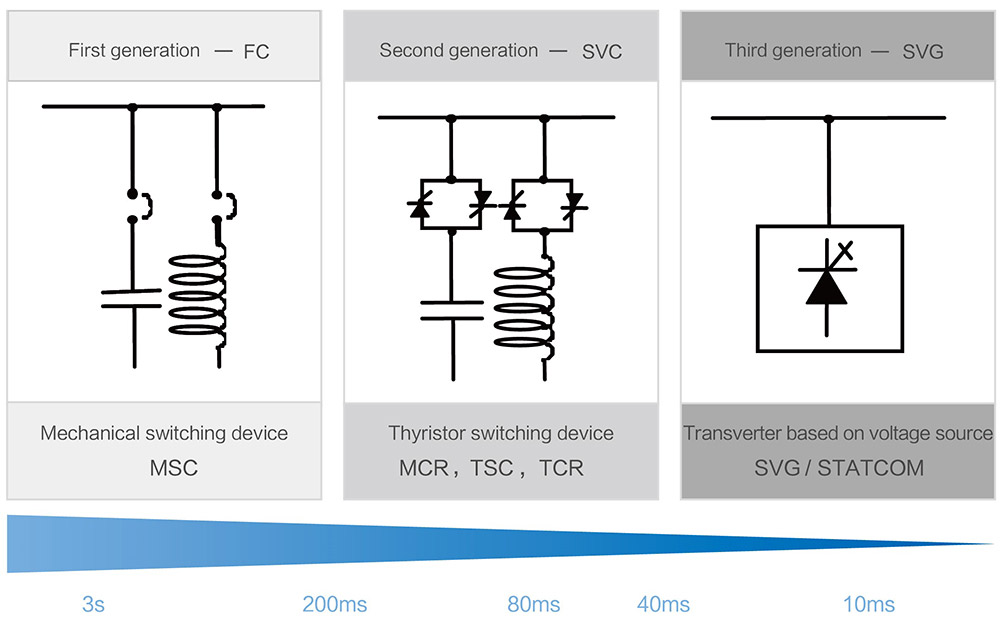

Compared to the first and second generation of reactive power compensation, the third generation Static VAR Generator (SVG) has outstanding advantages :

1.Comprehensive optimization of power quality: through dynamic reactive power compensation, harmonic content is reduced and power supply reliability is improved;

2.Fast response speed: under the drive of fully controlled devices, the response time can be controlled within 5 milliseconds to adapt to high-frequency load changes;

3.Two-way compensation capability: it can compensate for both inductive and capacitive reactive power, and flexibly adapt to complex scenarios such as photovoltaic grid connection and arc furnace;

4.Intelligent management: supports docking with smart grids to achieve remote monitoring and real-time analysis of power quality data.

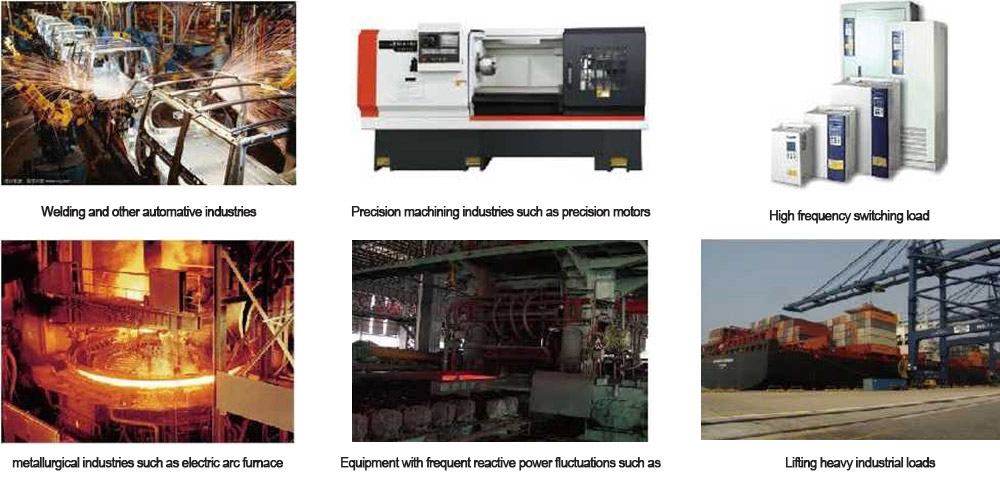

1.Fast response speed: SVG response time is less than 100μs, which can quickly complete capacitive/inductive reactive conversion and accurately compensate for impact loads;

2.Good safety performance: SVG is a current-controlled device with no resonance risk, which significantly improves the safety and stability of the power system;

3.Good compensation performance: A single set of SVG can simultaneously compensate for positive sequence (capacitive/inductive), negative sequence, zero sequence reactive power and harmonics, and three-phase imbalance;

4.Good compatibility: SVG can be flexibly combined with traditional compensation methods and uniformly controlled to adapt to the coordinated compensation needs of multiple scenarios.

Power Supply Voltage | 400Vx (1 ±20% ) or 690Vx (1 ±20%) |

Power Grid Frequency | 50 x (1 ±5%) Hz |

Response Time | <5ms |

Overall Efficiency | >97% |

Target Power Factor | Capacitive and inductive adjustable |

Compensation Method | Reactive power compensation, harmonic control and three-phase unbalanced compensation |

Parallel Operation | Up to 5 nuits |

Operation Display | LCD control panel, operating parameter setting, touch button operation, multi-parameter display |

Protection Functions | Device overcurrent, over-heat, grid under-voltage, grid phase mismatch, DC busbar under-voltage, overload automatic current limiting protection |

Cooling | Forced air cooling |

Protective Class | IP20, other IP class can be customized |

CT Ratio | 150:5-10000:5 |

Operating Environment Temperature | -20C~ +50°C |

Color | RAL7021 Black sand pattern(other color can be supplied if required ) |

Relative Humidity | <90%(25°C) |

Noise | <65dB |

Communicaiton | MODBUS RTU( RS485)Ethernet communication function is optional, upper computer monitoring software is optional |

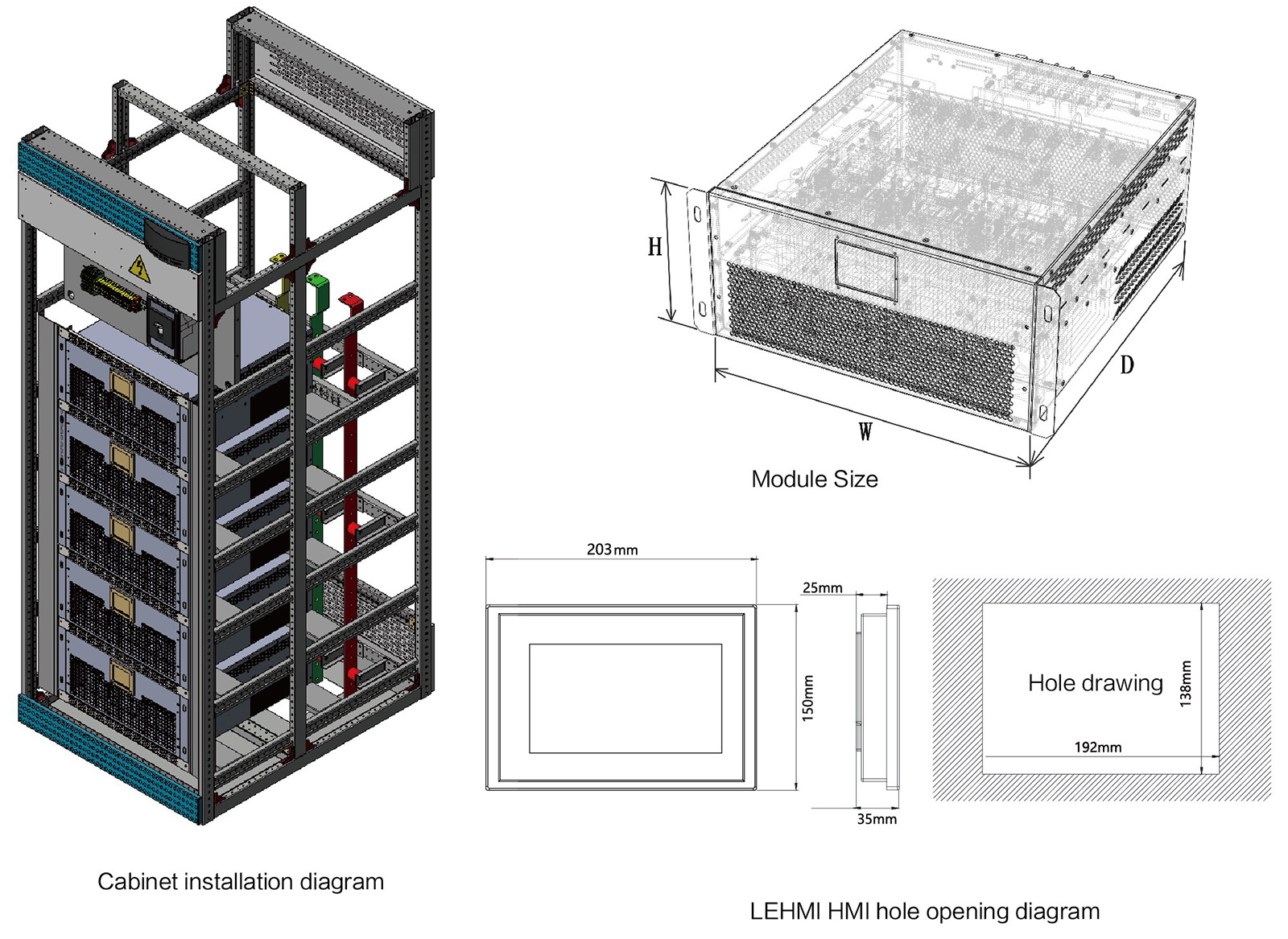

Rated capacity | Model | Installation Dimensions(mm) | Installation Way |

(Kvar) | W×D×H | ||

30 | LHG400-30-M | 560x550x220 | Modular |

50 | LHG400-50-M | 560x550x220 | Modular |

75 | LHG400-75-M | 560x580x220 | Modular |

100 | LHG400-100-M | 560x580x220 | Modular |

| 125 | LHG400-125-M | 560*580*220 | Modular |

150 | LHG400-150-F | 800x800x2200 | Cabinet |

200 | LHG400-200-F | 800x800x2200 | Cabinet |

250 | LHG400-250-F | 800x800x2200 | Cabinet |

300 | LHG400-300-F | 800x800x2200 | Cabinet |

400 | LHG400-400-F | 1000x1000x2200 | Cabinet |

500 | LHG400-500-F | 1000x1000x2200 | Cabinet |

Model | LESVG400-500-F |

Main Components | LESVG400-100-M module *5 |

HMI *1 | |

High presicion sampling current transformers *3 | |

Accessories | Cabinet shell, MCCB, surge protector, terminal strip, date line |

| Classify | Title | Download |

|---|---|---|

| FaSVG SVG Operation Manual V2.1 | ||

| FaSVG SVG Operation Manual V3.0 |

Leave your contacts and our engineers will help you to find the solution you are looking for.

Hi! Welcome back.

How are you doing?

Let s talk! We’ll provide the perfect solution for you!

Lafaelt Electric is focusing on complete solutions for power quality and energy management. We have excellent quality in designing, researching, producing and manufacturing on Active harmonic filter, Static VAR generator(SVG), Power capacitor, Reactor, Thyristor switch, Dynamic voltage restorer and Active voltage conditioner.

Sales Center Add: No. 1, Xinyan Road, Xinwu District, Wuxi, Jiangsu Province, China

Factory Add:No.1, Xinyan Road, Xinwu District, Wuxi City, Jiangsu Province, China